WHAT ARE V-TEMS

Plasticized polymers with a range of durometers and toughness to meet various material requirements.

MATERIAL CHARACTERISTICS

OF V-TEMS

Viscous, high elongation, thermoplastic, non-toxic, cushioning, lubricating.

MODIFICATIONS AND ADDITIVES

Specific oils for exudation, fragrances, over-the-counter (OTC) additives, triglyceride based formulations.

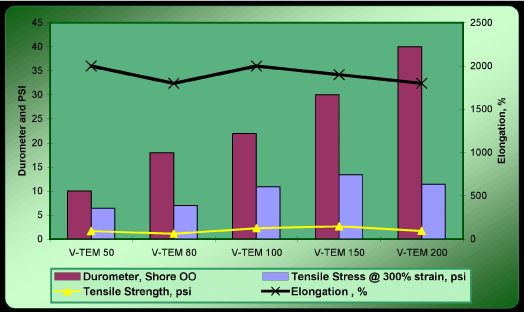

V-TEM PROPERTY DATA |

V-TEM 50 |

V-TEM 80 |

V-TEM 100 |

V-TEM 150 |

V-TEM 200 |

Durometer, Shore 00 |

10 |

18 |

22 |

30 |

40 |

Tensile stress @ 100% Strain, psi |

2.8 |

2.8 |

5.2 |

6.5 |

5.4 |

Tensile stress @ 300% Strain, psi |

6.4 |

7.0 |

10.9 |

13.4 |

11.4 |

Ultimate Tensile Strength, psi |

90.2 |

61.0 |

126 |

147 |

93.3 |

Tensile stress at break, psi |

77.9 |

54.2 |

111 |

135 |

90.7 |

Elongation, % |

2000 |

1800 |

2000 |

1900 |

1800 |

Compression Set (*) |

<1% |

<1% |

<1% |

<1% |

<1% |

Glass transition temperature, Tg, ºC |

< (-50ºC) |

< (-50ºC) |

< (-50ºC) |

< (-50ºC) |

< (-50ºC) |

(*) Compression Set testing is performed at room temperature on a sample compressed ~50% of its thickness, held for 24 hours, then released and allowed to relax for 3 hours. Compression set is expressed as a percentage of the original deflection.

Back to Top

V-TEMS are visco-elastic thermoplastic elastomers (TPE’s).

This means these materials can hold a shape, exhibit high degrees of elongation, and can be melted, solidified, and remelted with minimal or no loss of properties. Read more

How We Work

We work on a client by client basis. No request is too small or too large. Go ahead and tell us about your project and we'll respond ASAP with a solution. Read more